Warehouse managers face increasing pressure in 2026 as indoor air quality becomes a top concern. Stricter regulations and rising employee expectations make it essential to address this challenge head on.

Poor air quality in warehouses can lead to serious health problems, reduced productivity, and costly compliance penalties. It is no longer just a regulatory issue, but a critical factor for safe and efficient operations.

Warehouse air quality monitoring is now a proactive strategy for ensuring safety, compliance, and operational excellence. This guide will walk you through the latest regulations, monitoring technologies, step by step implementation, and future trends to help you stay ahead.

Understanding Warehouse Air Quality: Risks and Regulations

Concerns about warehouse air quality monitoring have never been more pressing. With evolving regulations and growing awareness, managers must understand the specific risks and rules shaping the industry. This section explores the main hazards, regulatory frameworks, and the reasons monitoring is vital for warehouses in 2026.

Key Air Quality Risks in Warehouses

Warehouses face a variety of air quality challenges. Common pollutants include dust, particulate matter, volatile organic compounds, carbon monoxide, and chemical fumes. These contaminants often result from vehicle emissions, machinery, packaging, cleaning agents, and the storage of hazardous materials.

The health impacts are significant. Workers exposed to poor air can experience respiratory problems, allergies, and even chronic conditions. Increased absenteeism is a common consequence, with studies indicating that warehouses with substandard air quality report up to 30 percent higher sick leave rates.

Risks extend beyond health. Dust accumulation can damage sensitive machinery, leading to higher maintenance costs and operational downtime. Reduced worker efficiency and morale are additional concerns. This illustrates why warehouse air quality monitoring forms the backbone of a safe and productive workplace.

UK and Global Warehouse Air Quality Regulations

Regulations for warehouse air quality monitoring are tightening both in the UK and internationally. In the UK, employers must comply with COSHH and HSE guidelines, which require risk assessments and effective control of hazardous substances. International standards, such as OSHA regulations in the US and EU directives, also set strict requirements for monitoring and reporting air quality.

Employers are legally obligated to conduct regular assessments, maintain records, and implement ongoing monitoring. Failure to comply can result in fines, legal actions, and reputational damage. Recent enforcement actions highlight the real financial and operational risks of non compliance.

For warehouses handling airborne particulates, understanding UK air quality monitoring requirements for PM2.5 is essential. These requirements clarify the targets and monitoring obligations affecting warehouse operations. Staying informed about such obligations is key to maintaining compliance.

Why Monitoring Matters in 2026

Looking ahead, warehouse air quality monitoring is more important than ever. Regulatory bodies are increasing inspections, and new standards are expected in 2026. Employees are also more aware of air quality issues, demanding safer working conditions and transparency.

Insurers now require documented air quality monitoring as part of their risk assessments. This shift reflects the broader industry trend towards proactive safety management. According to a 2025 survey, 67 percent of warehouse managers plan to upgrade monitoring systems in response to regulatory changes.

Continuous monitoring not only ensures safety and compliance but also supports operational efficiency. By investing in warehouse air quality monitoring, managers can stay ahead of legal changes, protect their workforce, and optimise productivity.

Essential Technologies for Warehouse Air Quality Monitoring

Modern warehouse air quality monitoring is advancing rapidly, offering powerful tools to protect staff, comply with regulations, and optimise operations. Understanding the range of available technologies helps managers make informed decisions that ensure healthier, more productive workplaces.

Types of Air Quality Sensors and Systems

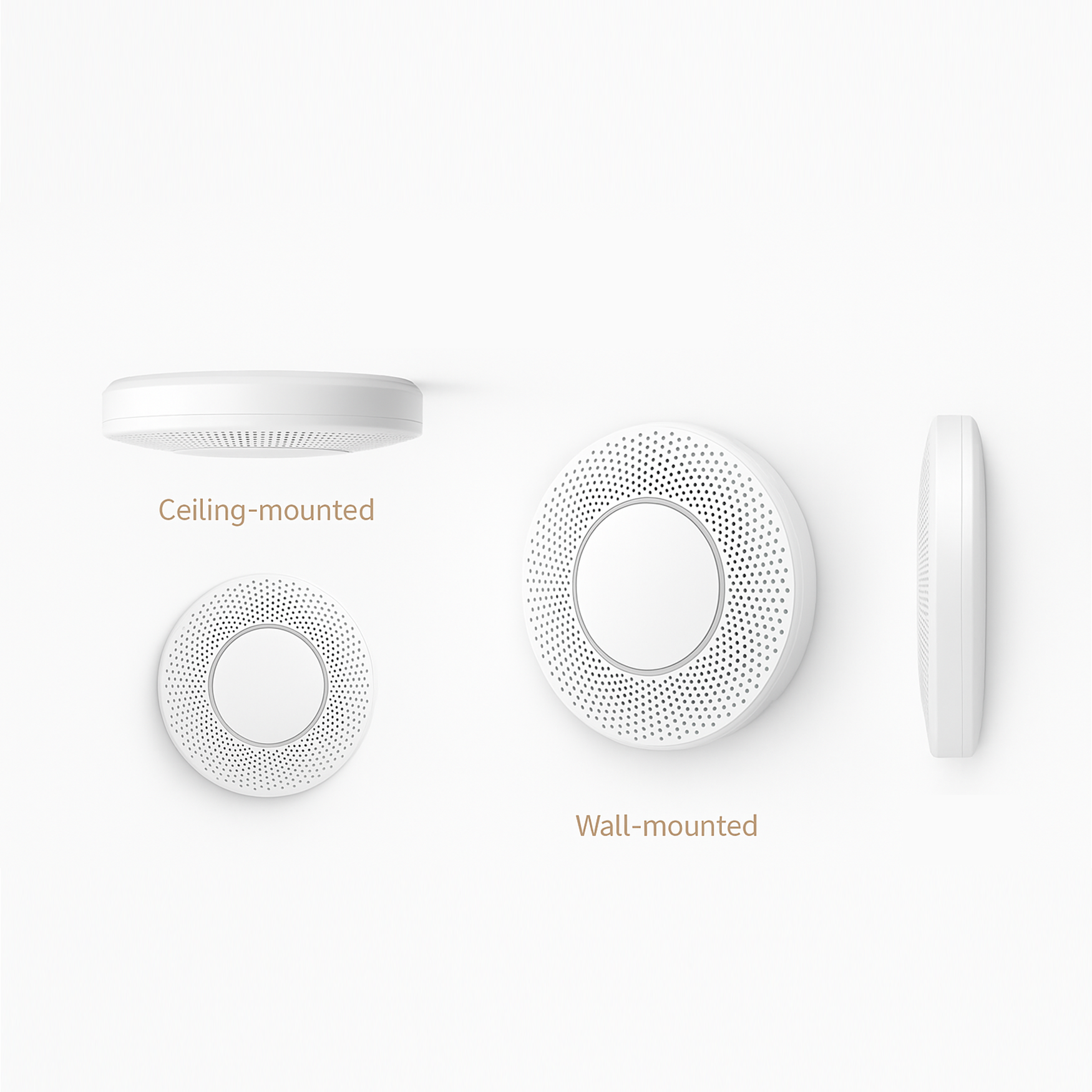

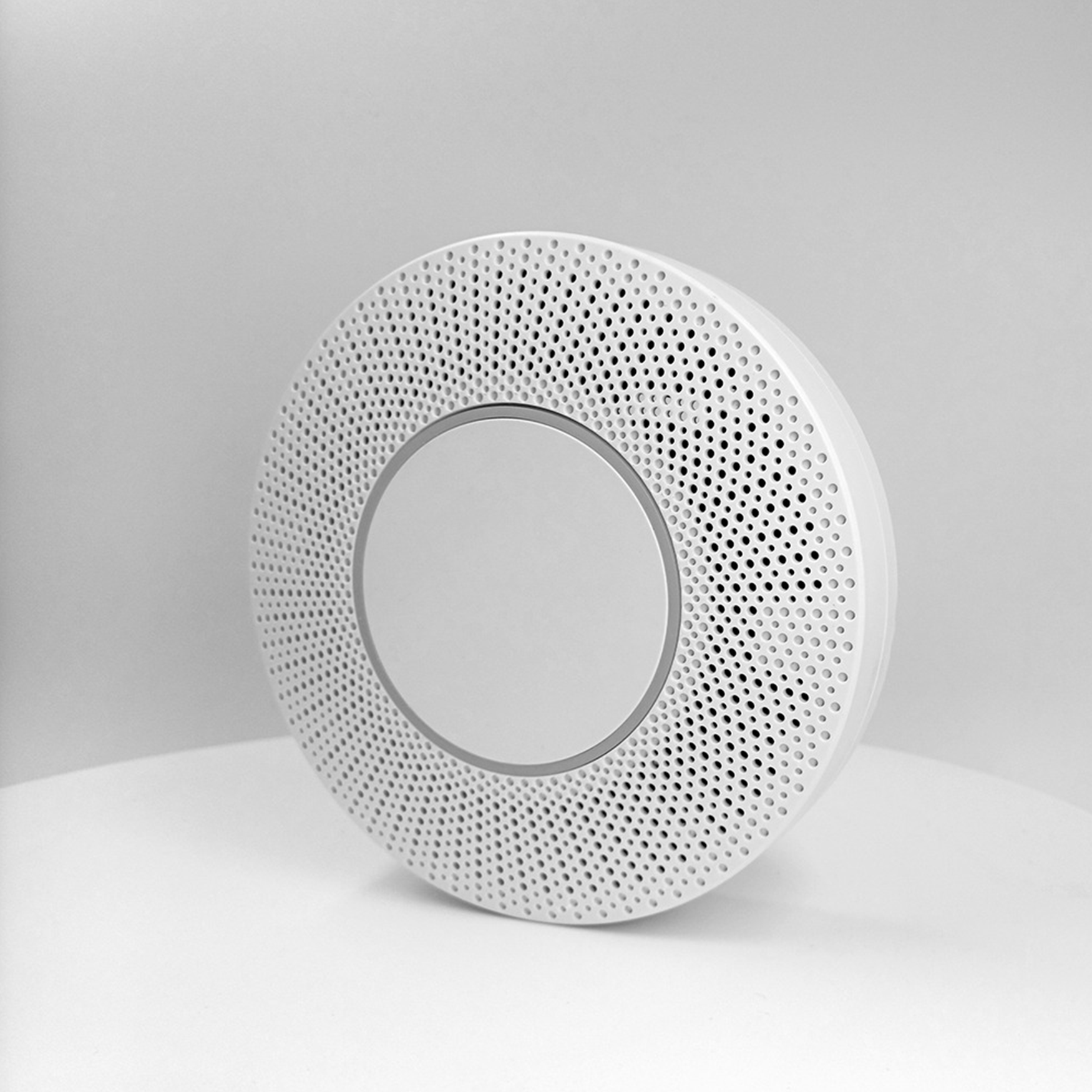

Selecting the right sensors is the cornerstone of effective warehouse air quality monitoring. Facilities typically choose between fixed and portable sensors. Fixed sensors offer continuous surveillance in key locations, such as loading docks and storage areas. Portable units, in contrast, allow for flexible spot checks in changing environments or temporary risk zones.

Key sensor types include:

- Particulate sensors for dust and PM2.5 detection

- Gas sensors to identify carbon monoxide or nitrogen dioxide

- Volatile Organic Compound (VOC) sensors for chemical vapour monitoring

- Humidity sensors to manage condensation risk

Integration with building management systems and IoT platforms enables automatic data flow and centralised control. Real time monitoring is increasingly favoured, as it enables swift responses to air quality incidents. For a deeper dive into the technologies behind modern sensors, review the Smart sensor technology overview.

Data Collection, Alerts, and Reporting Features

Robust data collection is essential for warehouse air quality monitoring. Automated data logging ensures that all measurements are recorded accurately and securely, often using cloud storage for easy access and backup.

Customisable alert thresholds allow managers to set limits for specific pollutants. When these thresholds are breached, instant notifications enable prompt actions to protect staff and assets. Detailed reporting features simplify compliance with regulatory requirements, offering clear documentation for audits and inspections.

A practical example: one UK warehouse avoided a hazardous exposure incident after their automated system triggered alerts when VOC levels rose unexpectedly. This rapid response prevented potential health risks and operational delays.

Selecting the Right Solution for Your Warehouse

Choosing the best warehouse air quality monitoring system requires careful consideration. Key factors include facility size, the types of pollutants present, and how the monitoring solution integrates with existing workflows. Scalability is vital, as needs may change with new regulations or operational shifts.

Cost considerations extend beyond initial investment. Maintenance, ongoing calibration, and staff training are critical for sustained performance. Future proofing is also important, as monitoring technologies must adapt to evolving standards and risks.

A comparison table can help summarise these considerations:

| Factor | Considerations |

|---|---|

| Facility Size | Number of sensors required |

| Pollutant Types | Sensor selection |

| Integration | Compatibility with systems |

| Scalability | Expansion capability |

| Cost | Upfront and ongoing expenses |

| Compliance | Adaptability to new rules |

By carefully weighing these factors, managers can ensure their warehouse air quality monitoring programme remains effective and resilient.

Step-by-Step Guide: Implementing Warehouse Air Quality Monitoring in 2026

Effective warehouse air quality monitoring is essential for ensuring safety, compliance, and operational efficiency in 2026. The following step-by-step guide provides a clear pathway for warehouse managers to assess, plan, and implement robust monitoring systems that meet current and future standards.

Step 1: Assess Current Air Quality and Identify Risks

Start by conducting a thorough assessment of your warehouse air quality monitoring needs. Measure baseline air quality using portable or fixed sensors to gather initial data on pollutants like dust, VOCs, and carbon monoxide.

Map out the warehouse to identify pollutant sources such as vehicle emissions, packaging areas, and storage of chemicals. Pinpoint high-risk zones where air quality may fluctuate, including loading bays and cleaning stations.

Engage your workforce by soliciting feedback on perceived air quality issues. Employees often notice concerns that automated systems might overlook, adding valuable insights to your assessment.

Document all findings carefully. This creates a reference point for future improvements and serves as evidence for regulatory compliance. By prioritising warehouse air quality monitoring at the assessment stage, you lay the groundwork for a safer, healthier workplace.

Step 2: Define Monitoring Objectives and Compliance Goals

With your baseline established, set clear objectives for warehouse air quality monitoring. Decide whether your primary goals are to reduce health risks, maintain compliance, or improve operational efficiency.

Align your strategy with UK regulations such as COSHH and HSE, as well as any international standards relevant to your operations. This ensures your monitoring meets both legal and industry requirements.

Determine key performance indicators (KPIs) for air quality, like acceptable levels of particulates or VOCs. These KPIs will guide your ongoing monitoring and help measure success.

Communicate your objectives and compliance goals to all stakeholders. Transparency in your warehouse air quality monitoring programme builds trust and ensures everyone understands their responsibilities.

Step 3: Select and Install Appropriate Monitoring Technologies

Evaluate which monitoring technologies best suit your facility. Consider sensor types such as particulate, gas, and VOC sensors, as well as their compatibility with your warehouse air quality monitoring strategy.

Plan sensor placement to ensure comprehensive coverage. Focus on high traffic zones, storage areas, and locations with potential for pollutant accumulation. Use both fixed and portable options if needed.

Ensure new sensors and systems integrate seamlessly with existing building management tools and IoT platforms. This supports real-time monitoring and efficient data collection.

Schedule professional installation and calibration. Proper setup is critical for accurate warehouse air quality monitoring and long-term reliability.

Step 4: Establish Monitoring Protocols and Response Plans

Develop clear protocols for ongoing warehouse air quality monitoring. Set up automated data collection and cloud-based storage for continuous tracking.

Define alert thresholds for each pollutant. Establish escalation procedures so staff know how to respond when air quality deteriorates.

Provide training for all relevant personnel. Staff should understand how to interpret monitoring data and act quickly in the event of alerts.

Document all protocols and response plans. This documentation supports audits, inspections, and demonstrates your commitment to a safe working environment.

Step 5: Review, Analyse, and Optimise Monitoring Programme

Regularly review the data collected from your warehouse air quality monitoring system. Look for patterns, anomalies, and trends that indicate areas for improvement.

Conduct periodic audits and recalibrate sensors to maintain accuracy. Adjust protocols or sensor placement as warehouse operations evolve.

Leverage real-world examples to benchmark your results. Case studies, such as those found in Vape Guardian case studies, demonstrate how ongoing monitoring and optimisation can lead to significant reductions in incidents and improvements in compliance.

By continuously analysing and refining your warehouse air quality monitoring programme, you ensure it remains effective, future-proof, and aligned with evolving regulations.

Analysing and Leveraging Air Quality Data for Continuous Improvement

Warehouse air quality monitoring has become an essential pillar for maintaining safe, compliant, and efficient operations. The true value of monitoring lies not only in collecting data, but in transforming this information into actionable strategies. By systematically analysing air quality data, warehouse managers can pinpoint issues, implement targeted improvements, and demonstrate measurable progress to stakeholders.

Turning Data into Actionable Insights

Interpreting data from warehouse air quality monitoring systems is the first step towards meaningful change. Managers should examine readings for patterns, such as peak times for particulate matter or spikes in volatile organic compounds. These patterns often reveal the root causes of air quality issues, whether from forklift emissions, packaging materials, or cleaning activities.

Advanced analytics platforms and dashboards can simplify this process. Visual tools allow real time tracking, while historical data trends support more strategic decisions. For example, a warehouse might discover that PM2.5 concentrations rise during morning deliveries. By referencing PM2.5 air quality reports, managers gain deeper context on the impact of fine particulates in warehouse environments.

Using warehouse air quality monitoring data in this way empowers teams to act before issues escalate. Identifying pollution sources early reduces health risks and supports continuous improvement.

Implementing Targeted Interventions

Once insights are drawn from warehouse air quality monitoring, targeted interventions can be planned. The most effective strategies are those tailored to your facility’s unique needs and operational rhythms.

Common interventions include:

- Upgrading ventilation and filtration systems to remove particulates and chemical fumes

- Adjusting schedules for high emission tasks, such as operating diesel vehicles during low occupancy hours

- Switching to electric forklifts or using low emission packaging materials

Warehouse air quality monitoring data enables managers to measure the impact of each intervention. For instance, after installing new air filtration, a warehouse may observe a marked decrease in dust levels across key zones. Regular review of intervention outcomes ensures that strategies remain effective as operations evolve.

Measuring Impact and Reporting Outcomes

Assessing the results of warehouse air quality monitoring efforts is crucial for accountability and continuous progress. Quantitative metrics, such as reductions in PM2.5, carbon monoxide, or VOCs, provide clear evidence of improvement. Warehouses often track additional indicators, including:

- Lower absenteeism due to respiratory issues

- Fewer equipment breakdowns from dust accumulation

- Enhanced employee satisfaction and retention

Reporting these outcomes to management, employees, regulators, and insurers builds trust and demonstrates commitment to health and compliance. Some warehouses have even secured reduced insurance premiums after documenting sustained air quality improvements.

By closing the loop from monitoring to reporting, warehouse air quality monitoring delivers lasting value across safety, compliance, and operational excellence.

Future Trends in Warehouse Air Quality Monitoring for 2026 and Beyond

As warehouse air quality monitoring becomes more advanced, the landscape is rapidly evolving. Over the next few years, new technologies, regulatory changes, and sustainability goals will reshape how warehouses maintain optimal air quality. Staying ahead of these trends will be essential for effective risk management and operational resilience.

Emerging Technologies and Innovations

The future of warehouse air quality monitoring will be driven by cutting edge innovations. Artificial intelligence is set to revolutionise monitoring by enabling predictive analytics for early detection of air quality risks. IoT integration will allow sensors to communicate with building management and automation systems for instant responses.

Wearable air quality monitors are also gaining traction, providing real time data directly to staff and supervisors. Research into AI in environmental monitoring systems highlights the potential for energy efficient, multi modal sensors that can process data at the edge, reducing latency and supporting faster decision making.

Evolving Regulations and Industry Standards

Regulations governing warehouse air quality monitoring are becoming more stringent both in the UK and globally. The UK government’s DEFRA air quality target delivery plan outlines ambitious targets for air quality improvement, requiring warehouses to adopt robust monitoring and transparent reporting practices.

Internationally, alignment with EU directives and global standards is expected to increase, pushing for greater data transparency and accountability. Warehouse operators will need to keep pace with frequent updates to legislation and demonstrate compliance through documented monitoring.

The Role of Sustainability and Corporate Responsibility

Sustainability is now at the forefront of warehouse air quality monitoring. Companies are increasingly linking monitoring efforts to ESG (Environmental, Social, Governance) objectives, recognising that air quality impacts both environmental performance and social responsibility.

Customers and investors are demanding greater transparency in how warehouses manage air quality. Demonstrating a proactive approach through monitoring can enhance corporate reputation and help secure long term business partnerships.

Preparing for the Warehouse of the Future

Looking ahead, warehouse air quality monitoring must adapt to new operational models. As automation, robotics, and smart logistics systems become standard, monitoring strategies will need to support these advancements without disrupting workflow.

Smart warehouses are already leveraging integrated air quality and safety systems to boost resilience and efficiency. By future proofing monitoring programmes, warehouses can ensure they remain compliant, sustainable, and ready for emerging challenges.

As you look ahead to 2026, ensuring the air quality in your warehouse isn’t just about compliance—it’s about creating a safer, healthier, and more productive environment for everyone on your team. We’ve covered the essential strategies and technologies you’ll need to stay ahead of regulations and protect your staff from hidden risks. If you’d like expert guidance on the best solutions or want to discuss how to tailor air quality monitoring to your unique needs, don’t hesitate to talk to our team and protect your building today. Your next step towards a safer workplace starts here.

Share:

Factory Air Quality Monitoring: The 2026 Expert Guide

Multi-Sensor Detection Platform Guide: Your 2026 Roadmap